Manufacturing method of flip-flops

- Never forget traditional manufacturing method.

- Every sandal is made wholeheartedly.

All sandals of Tsukumo are handmade. Since 1950, due to pursue of comfort, Japanese flip-flops manufacturing method has been pass down till today. By undergo many practices, we create better and better product.

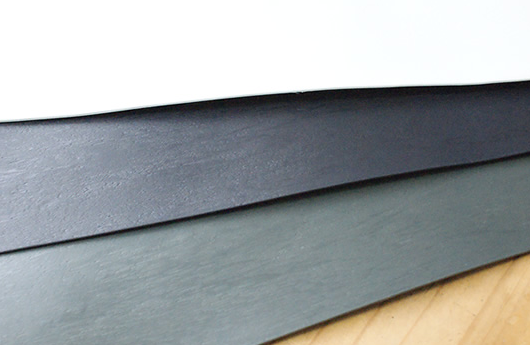

1.Production of rubber sole.

Flip-flops is made with a rubber sole and strap. The rubber plate is what goes under the sole. The rubber sheet is created by heat and pressure. Even though the difference in height of the rubber has been created at this point, there are many factors that will affect the final product such as weather, room temperature, color, and expansion of the rubber. All of these factors are adjusted according to the sensitivity and experience of our craftsmen.

2.Sole Cutting

After the completion of rubber sheet, it then goes through the cutting process. According to the size of the rubber sheet, one sheet can produce around 20 pieces of sole. The position of the cuts is extremely important. If cuts are incorrect, then the heights of the front and back sole will be different between one another. Different Heights will cause discomfort when wearing. The precision of the cuts is depended on years of experience of the workers. Long time ago, the sole cutting process were giving to a professional Cutting Plant.

3.Hole drilling

In order to fit the straps perfectly into the sole, holes were made slightly bigger when drilled. This is another process that looks very easy but difficult to complete. If the depth of the hole gets too deep, it can cause the strap to go through. If the hole is too shallow, it becomes vulnerable and breaks easily. Hole drilling is also another process done by the hands of our workers. A total of six holes are drilled onto each pair of flip-flops.

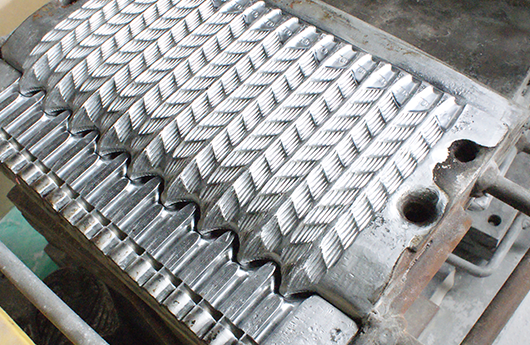

4.Creation of straps

Straps are made from natural rubbers. The rubber goes through process of kneading and color dying. The rubber is then place into a mold, which has heat and pressure, to create the straps. (The straps are connected at this point. It is yet the final product.)

5.Form strap into shape

Form a “bundle” of straps into pieces of straps. It is also a simple work but all of them should be cut with a scissors by manual work. Rough edges may remain on the strap with poor cutting and or by a blunt knife. These flaws could cause pain to the foot. It is important to maintain both speed and quality when making straps. The fun part of hand making the product is that you could tell who made the product by its quality.

6.Attach the strap

The process of attaching strap on the rubber sole is called “Sugeru”

Use a special tool to attach the strap through the 3 holes. This is a simple task but require lots of strength. It would be easy to fit the strap through a big hole but it would fall off easily. This process needs a precise balance.